NVISION is a San Antonio-based medical device and biologics company focusing on providing surgeons with implants and biologics that simplify and improve surgery procedures.

Our Products

About NVISION

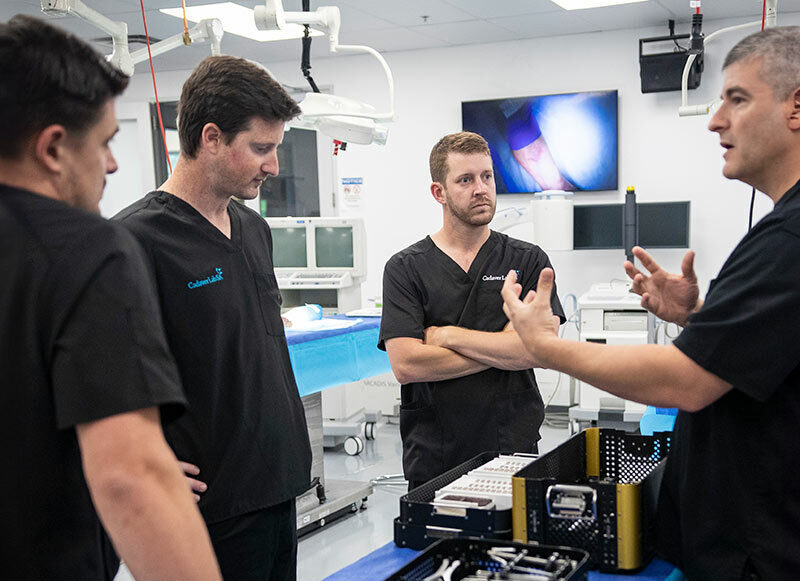

Founded in 2013, NVISION boasts more than 100 years of combined experience and relationships in the industry. We are committed to meeting our customer’s needs with the highest quality medical products to provide treatment or diagnosis options where orthopedic implant devices are indicated.

Our Brands